The Future of Flexible Electronics: Efficient Integration of Mica Substrates and BiFeO3 Ferroelectric Materials

With the rapid advancement of wearable devices, foldable displays, and smart medical sensors, "flexibility" in electronic components has become a core competitive frontier in material science. However, maintaining high-performance functionality while ensuring extreme physical flexibility presents a significant technical hurdle. Specifically, in the field of non-volatile memory, integrating high-quality Ferroelectric Material onto flexible substrates remains a peak that scientists are eager to scale.

The Role of Buffer Layers: Overcoming Lattice Mismatch

Recent research has provided a breakthrough solution to this challenge. Studies indicate that by introducing a SrTiO3 (STO) buffer layer onto a Mica substrate, the crystalline quality of BiFeO3 (BFO) thin films can be significantly enhanced.

BiFeO3 is a multiferroic material that exhibits both ferroelectricity and ferromagnetism at room temperature, making it an ideal candidate for flexible memory. However, traditional substrates like Silicon (Si) lack physical flexibility, while organic polymer substrates cannot withstand the high-temperature environments required for BFO growth. Mica has emerged as an excellent alternative due to its superior heat resistance and atomically flat cleavage planes. Nevertheless, the lattice constant difference between Mica and BFO often leads to defects in the thin film.

The research team solved this by utilizing a dual-buffer structure consisting of SrTiO3 (STO) and La0.65Sr0.35MnO3 (LSMO). This structure acts as a precision foundation on uneven ground, not only relieving interfacial strain but also enabling the high-quality epitaxial growth of the BFO film. This allows the Ferroelectric Material to achieve near-perfect atomic alignment even on a flexible base.

Exceptional Fatigue Resistance and Mechanical Robustness

According to the data published in Scientific Reports, the optimized Pt/BFO/LSMO/STO/mica structure demonstrates breathtaking performance. After undergoing 108 bipolar switching cycles, the polarization degraded by a mere 0.28%. This level of fatigue resistance implies that the device can maintain data stability even after long-term, high-frequency read/write operations. Furthermore, in mechanical stress tests, the ferroelectric properties remained largely unchanged even when the bending radius was reduced to 3.5 mm.

Behind these impressive figures lies a critical measurement challenge: how does one accurately capture such minute degradation? For R&D personnel, if the measurement equipment has a high noise floor or insufficient frequency response, critical details of material optimization can easily be missed.

Precision Measurement: Why a High-End Ferroelectric Analyzer is Mandatory

When evaluating the commercial potential of BFO thin films, the most vital physical parameter is Remanent Polarization (Pr). It directly determines how much charge signal the memory can retain after power is removed. However, flexible films under bending conditions experience complex electromagnetic environments. Traditional testing equipment often struggles to distinguish "true polarization" from "false signals" caused by leakage current.

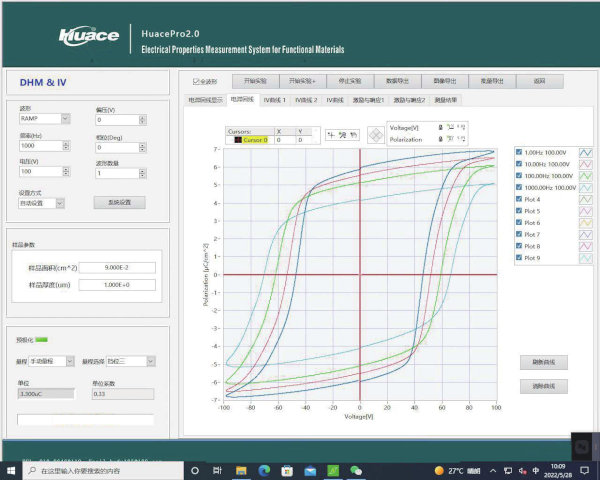

P-V Chart of Dynamic Hysteresis Measurement

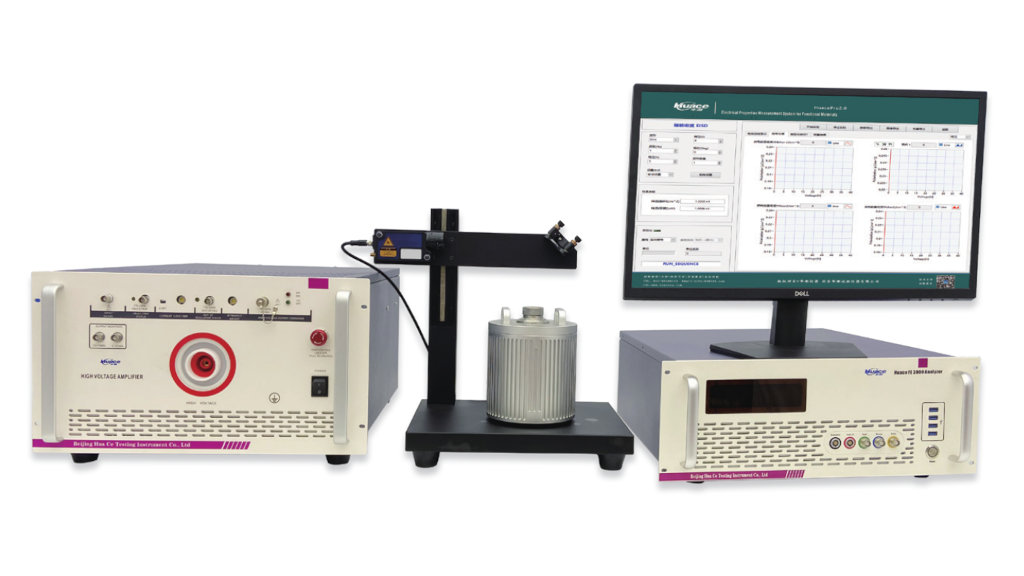

This is where a professional-grade Ferroelectric Analyzer becomes indispensable. Take the ACTTR Ferroelectric Analyzer as an example: it features an industry-leading test frequency of up to 270kHz, which effectively filters out non-ferroelectric contributions. More importantly, the system’s built-in PUND (Positive Up Negative Down) test module uses precise pulse sequences to completely eliminate the interference of leakage current on Remanent Polarization values, allowing researchers to obtain the most authentic material parameters.

In addition, BFO often requires high-voltage excitation for saturation. The ACTTR Ferroelectric Analyzer offers powerful modular scalability. Its built-in ±200V range can be easily expanded to 4kV or even 10kV through external power amplifiers, meeting the comprehensive testing needs of everything from thin films to large-scale bulk ceramics.

Conclusion: The Right Tools for the Task

The combination of Mica substrates and STO buffer layers has paved the way for flexible BiFeO_3 devices. However, material development is only the first step; precision data characterization is the ticket to industrial application. For laboratories dedicated to Ferroelectric Material research, choosing a stable, full-featured Ferroelectric Analyzer is not just about obtaining a clean hysteresis loop—it is about accurately locking in every bit of progress across 10^8 cycles to optimize the most competitive product for the market.

For more information, please Contact ACTTR right away, we're please to serve you!