Evolution of DSC - C80 3D Calvet Calorimeter

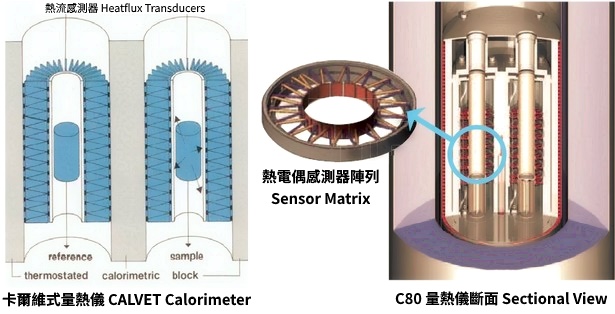

C80 uses the latest evolution of the Calvet Design calorimetric detector in which a sample and reference cell are totally surrounded by an array of thermocouple detectors allowing for the measurement of all heat evolved (or adsorbed) including radiation, convection or conduction.

C80 is the best calorimeter for studying complex chemical reactions. With it's big chamber of reaction/reference surrounded by more than 300 thermocouples, a cell with a much bigger volume and very large choice of them (for in‐line pressure measurement, mixing, gas introduction, etc).

C80 3D Calvet Calorimeter Internal Structure

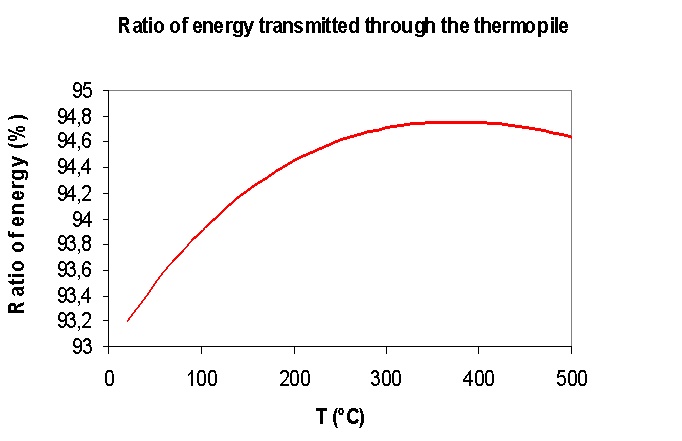

The Calvet detector is up to 94% efficient whereas typical plate DSC are between 20-40%, and as such the C80 provides for an unparallel precision of measurement independent of sample nature or matrix – solid, liquid, gas, powder etc.

The calibration of any calorimetric detector is a key parameter in it’s performance and with the Calvet detector the so-called Joule effect or electrical calibration, is used.

Features & Benefits

A dedicated vessel with a built-in electrical heater (platinum resistance) is used to simulate the experimental vessel containing the sample, and calibration is carried out using a series of precise heat inputs. The main advantages of this type of calibration:

- It is an absolute calibration

- It is not needed to use metallic reference materials

- The calibration can be performed at a constant temperature, or in scanning (either heating or cooling)

- It can be applied to any experimental vessel volume calibration

The sample, within a measurement vessel, is placed directly into the center of the measurement zone each of which has a total of 9 concentric rings, each containing 38 thermocouples (324 in total) to form a cylinder that totally surrounds both sample and reference and because all the heat is measured these vessels can be designed and configured to suit your application and process.

Setaram offers a comprehensive range of standard vessels (and a custom design service) to allow you to simulate your process conditions precisely and therefore negate the need for dangerous assumptions and calculations. These vessels include a range of standard and high pressure vessels up to 1000 bar (14,600psi) and a range of mixing and dissolution vessels for different sample behaviours, from viscous liquids to dynamic mixing options.

In summary the C80 Calvet detector is a highly precise calorimetric block that allows for an unmatched level of versatility because of the ability to use a wide range of sample vessels. Whether you are looking for highly precise heats of solution, interactions between gaseous agents and solid catalysts or even high pressure sample runaways for process safety that C80 from Setaram provides a precise, flexible and easy to use solution that can be easily housed on any laboratory benchtop. And the result can be analyzed by the professiona Thermal Analysis Software, AKTS (Advanced Thermal Analysis Software), in which allows user to apply thermokinetics analyzing with C80.

Numerous Professional Cells / Vessels

There is a wide range of vessels available for the C80 calorimeter. The cells can be closed (“batch” type) or combined with fittings to introduce reactive agents (“flow” type). All the cells can be used either in isothermal or DSC mode.

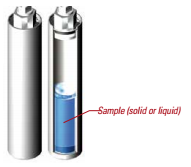

1. "Batch" Cell

For investigations on solids or liquids: transformation, decomposition, thermal behaviour, heat capacity of solid (a specific cell is available to measure heat capacity of liquid) studies:

- Cylindrical Hastelloy container with a cap, tightly closed without any link with the outside

- Available for regular (5 bar) and for high pressures (100 bar)

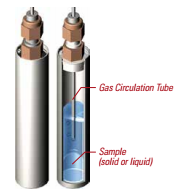

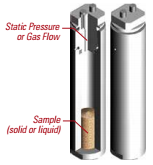

2. Gas Circulation Vessel

To study the effect of a gaseous atmosphere on a liquid or solid sample, oxidation, reduction, adsorption, hydrogenation or impact of controlled humidity.

To flow a liquid for investigations of liquid adsorption:

- Vessel with an inlet and an outlet in order to introduce a flow of fluid (gas, liquid) on the sample to be studied. Two coaxial tubes provide the inlet and the outlet of gas

- Available in two pressure versions: regular (5 bar) and 100 bar

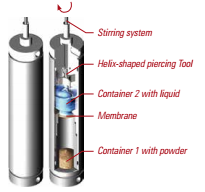

3. Membrane Mixing Cell

To study the mixing of two substances (solid or liquid) in order to measure the corresponding heat of interaction (especially adapted to viscous or heterogeneous mixtures):

- Two compartments are separated by a membrane. One substance is placed in the lower compartment (2.5 ml), the other in the upper compartment (2.9 ml). The two substances are brought together on perforating the membrane; the mixing is produced on rotating the perforator / stirrer. Stirring can be done manually or with the aid of a small motor

- Available in stainless steel or Hastelloy with membranes of aluminum or PTFE

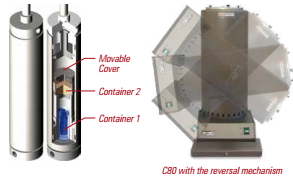

4. Reversal Mixing Cell

To study the mixing of two substances (solid or liquid) in order to measure the corresponding heat of interaction:

- Two different compartments are separated by a lid. One substance is placed in the lower compartment, the other in the above compartment.

- The mixing itself is obtained by inverting the calorimeter (using the reversal mechanism)

- Available in 3 volume versions (Lower/upper compartment): 0.6ml/5.0ml or 1.3ml/4.2ml or 2.5ml/2.0ml, made of stainless steel or Hastelloy

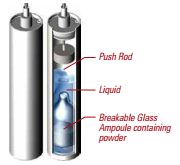

5. Ampoule Mixing Cell - Immersion Calorimetry

For studying reaction between a powder and a liquid (mainly wetting or hydration):

- The solid sample is placed inside the ampoule with the possibility to seal the ampoule under vacuum. The ampoule is then placed inside the body of the vessel containing the liquid

- Pressing the top of the rod will break the ampoule allowing the liquid and solid to mix

6. High Pressure “Batch” Cell

The High Pressure cell is used when the sample evolves pressure, through a decomposition for example.

For investigations on solids or liquids: transformation, decomposition, thermal behaviour, heat capacity of solid or a liquid:

- Cylindrical container with a cap, tightly closed without any link with the outside

- High Pressure up to 100 bar – Maximum – Temperature: 300°C Volume: 8.5 ml – Made of stainless steel or Hastelloy C276

- Reusable

7. Cell with Pressure Transducer

To record simultaneously the heat and pressure released by a sample. There is no need to control the pressure:

- The pressure resistant cell is connected to a high sensitivity pressure sensor though a special capillary tube. The cell is inside the C80 calorimeter, and the pressure sensor is outside, attached to the C80 structure. It is linked to the CALISTO Acquisition software, which allows recording the pressure signal as a function of time & temperature. The pressure is measured at the top of the cell, close to the sample

- Maximum Pressure: 350 bar – Maximum Temperature: 300°C Volume: 4 ml – Made of Hastelloy C276

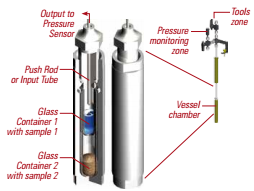

8. Process Safety Cell

To evaluate the synthesis reaction followed by product decomposition in a single experiment:

- The safety cell is composed of three main zones:

- the vessel chamber, made of stainless steel, and equipped with glass cells

- the tools zone for the insertion of breaking rods for batch mixing or injection tubes for controlled gas / liquid injections

- the pressure monitoring zone: pressure measurement, gas exhaust for further analysis, or simply to degas the system - Wide range of operations:

- Batch or semi- batch mixing at ambient pressure followed by decomposition with pressure measurement

- Gas flow for gas/liquid reactions or simply inerting of the reaction mixture

- Quantity of evolved gases can be determined from pressure measurement (up to 200 bar) - Maximum Pressure 200 bar – Maximum – Temperature: 300°C Volume: 6 ml – Stainless steel and glass liner

9. Controlled Static High Pressure Cell

To work under controlled and static pressure using a gas panel: to study gas hydrates formation/dissociation, to study adsorption and desorption:

- Maximum Temperature: 300°C

- Maximum Pressure: 1000 bar

- Volume 3.0 ml - Inconel 625

10. Controlled Dynamic High Pressure Cell

To work under dynamic mode (controlled pressure increase or decrease):

- Cylindrical Incoloy or Inconel container, tightly closed with two introduction tubes

- For measurements under dynamic pressure up to 600 bar

- Maximum Temperature: 500°C – Volume: 3.0 ml – Made of Inconel 625 or Incoloy

Applications

With its temperature range (ambient to 300°C) and its large range of cells the C80 calorimeter can meet a wide range of applications, especially when dealing with:

Life Sciences – Pharmaceuticals Products: polymorphism detection by dissolution studies, behavior of a drug under a wet atmosphere, study of polymorphism / crystallinity of drugs, amorphism, metabolism of living species, thermal stability of intermediate products

Process Safety: risks related to accidental pressure build up, synthesis of chemical followed by its thermal decomposition, thermal stability of substances, risks during normal operations, risks during an accident, time & mass scales

Energy: desulfurization of diesels by zeolithes, measure of reactivity of asphalt-salt mixtures, gas hydrates formation / dissociation, catalyzers characterization, adsorption of hydrogen (fuel cell), stability of nuclear waste, thermal characterization (nuclear)

Food: neutralization of free fatty acids in oils, gel formation / dissociation, dissolution studies, melting, crystallization, amorphism, stability vs. oxidation.