Evaluating Hiding Power of Pigments by A Particle Size Analyzer

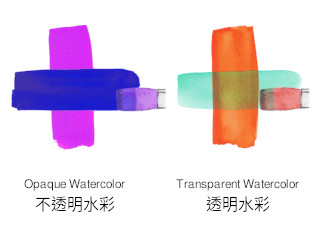

The "Hiding Power" of a pigment, also known as hiding strength or coverage, refers to the capacity of a coating or pigment to conceal the underlying surface or previous layers, effectively obscuring the color or pattern of the substrate. When we paint the wall or paintings layer by layer, the top layer of pigment can effectively cover the original color in the lower layer. Take watercolor painting as an example, when we applying opaque watercolor onto an existed color block, it can easily cover the underlying color (opaque watercolor has stronger hiding power), while the transparent watercolor cannot completely cover the lower layer, but it results the artistic effect of color layering or gradient (weak covering power).

The hiding power of pigments are of great significance to the manufacturing industries of paints, art paints, printing, etc., because it determines the ability of covering the surfaces with blemishes or dirt (opaque requirements), or to achieve gradual ability to layer artistic effects (semi-transparent requirements).

The Hiding Power Shows on the Watercolor Paint

The Relationship Between Hiding Power and Particle Size

The hiding power of mineral pigments is directly related to the particle size of the pigment powder. In general, smaller pigment particles has stronger hiding power because smaller particles can fill in small imperfections surface more easily. It results in a smoother, more uniform surface coating. In addition, smaller particles can reflect a stronger light scattering effect on the surface, thereby enhancing the hiding power of paints and pigments. Enhanced light scattering and reflection reduce the light penetrating and reflection from the coating, thereby improving the hiding power and color consistency of the pigment, and generating color gradation.

On the contrary, the larger the particle size of the pigment, it is easier to generate gaps between the particles. It allows light to penetrate into the gaps and reach the lower layer. Later, the light reflect the color of the lower layer through the upper layer of pigment, and the color of the lower layer shines through top layer.

Measuring the Hiding Power of Mineral Pigments Using a Particle Size Analyzer

Based on the above concepts, we can use a Laser Particle Analyzer Analyzer to measure the particle size of mineral pigments, and then we can know the relative hiding power of the pigment accordingly. Laser particle size analyzer is an instrument based on the principle of laser diffraction, which can measure the particle size distribution of all particles in the powder by the results of statistics.

The method of hiding power measurement is generally referring to ASTM D6441-05 international test standard. This standard measures the contrast ratio at a given film thickness of paints by a reflectometer, or measures the film thickness of the paints at 0.98 (98 %) contrast ratio by a thickness gauge. And the test methods in ASTM D6441-05 limited of coatings with a minimum CIE-Y reflectance of 15%. This method often requires a lot of repeated operations in order to obtain a stable and consistent reflectance or film thickness. It may not be an efficient way for industrial vendors. Besides, the painter's operation is not interested by the pigment manufacturers. For those paint and pigment manufacturers, they are more concerned about the influence of the characteristics of the pigment itself on the hiding power. Therefore, the particle size of the toner particles has become an important reference factor for pigment industries.

Bettersizer 2600 Particle Analyzer is launched by the international renowned manufacturer, Bettersize Instruments Ltd. which is the most suitable instrument for measuring the particle size of paints and pigments. Bettersizer 2600 Particle Analyzer can measure a variety of particles in both wet and dry methods. The modularized dispersion system in Bettersizer 2600 allows users to quickly switch measurement methods by themselves, either wet method or dry method. For most of the materials, the wet particle size analysis method can be used to obtain better dispersion result and make the measurement results more objective and consistent. For samples that are easily dissolved, the dry particle size analysis method can be used then. Bettersizer 2600 is definitely the best choice in verifying the hiding power of pigments.

Practice of Hiding Power Measurement

Pigments Powder Preparation

We use coral and lazurite as the pigment color materials. In the practice, we only care about the relationship between particle size analysis and ASTM D6441-05, rather than controlling the consistency of pigment powder quality, so, we can simply preparing different particle size of the pigment powder by controlling the grinding time. The longer the grinding time, we can obtain a smaller particle. In this practice, we use 30 seconds of grinding, 60 seconds, and 90 seconds of three particle sizes from the raw material, and get 4 kinds of samples (include the raw material) for the measurement.

After the powder are prepared, we visually observe the color of these powder samples, we can easily find that the coarsest particles milled for 30 seconds have better color saturation but lower brightness. Conversely, grind the finest particles for 90 seconds, the color saturation is lower, but with better brightness.

Pigments Raw Materials for Experiments

Two Types of Pigment Powder After Grinding, 3 Different Particle Sizes of Each

(Graph & Data Origin: Bettersize Instruments Ltd.)

Particle Size Analysis Results

By using Bettersizer 2600 Particle Size Analyzer, we tested the particle size distribution of the above six pigment samples one by one (include the raw material).

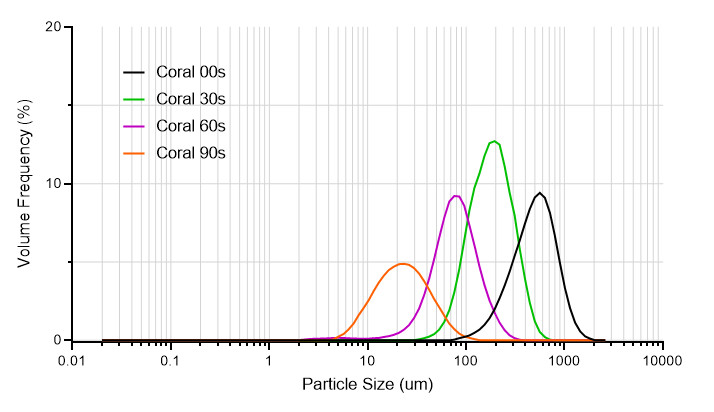

Samples of Coral Powder:

Below are the particle size measurements of the coral powder, from right to left are raw material (00s), and the pigment powder milled by 30 seconds, 60 seconds and 90 seconds.

|

Sample |

Dv10(㎛) |

Dv50(㎛) |

Dv90(㎛) |

|---|---|---|---|

|

Coral Raw Material |

221.8 |

473.2 |

841.8 |

|

Cpral 30s Grinded |

101.9 |

177.6 |

301.4 |

|

Cpral 60s Grinded |

34.47 |

72.43 |

137.3 |

|

Cpral 90s Grinded |

7.674 |

21.33 |

73.38 |

Coral Sample Particle Size Distribution Results

(Graph & Data Origin: Bettersize Instruments Ltd.)

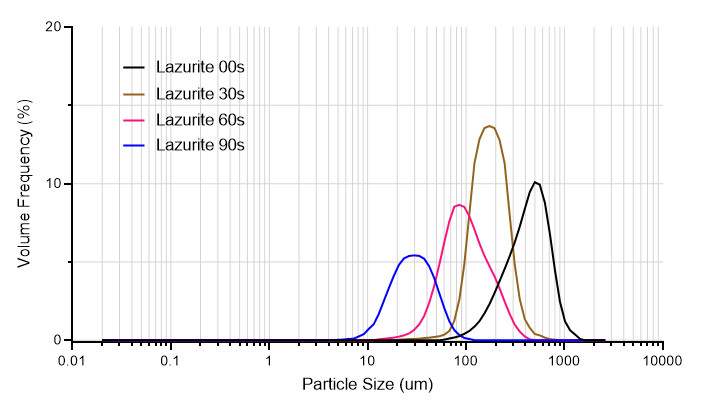

Samples of Lazurite Powder:

Below are the particle size measurements of lazurite powder, from right to left, the raw material, and the toner milled for 30 seconds, 60 seconds, and 90 seconds.

|

Sample |

Dv10(㎛) |

Dv50(㎛) |

Dv90(㎛) |

|---|---|---|---|

|

Lazurite Raw Material |

189.2 |

413.7 |

689.1 |

|

Lazurite 30s Grinded |

106.3 |

161.6 |

239.8 |

|

Lazurite 60s Grinded |

46.76 |

89.58 |

196.3 |

|

Lazurite 90s Grinded |

13.08 |

28.61 |

53.75 |

Lazurite Sample Particle Size Distribution Results

(Graph & Data Origin: Bettersize Instruments Ltd.)

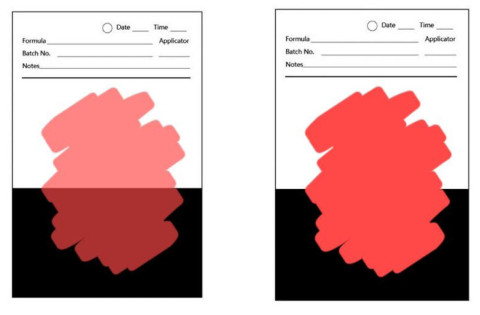

Standard Method ASTM D6441-05 Execution

The final determination of the hiding power of the pigment samples is based on the international standard method, ASTM D6441-05. Following ASTM D6441-05 standard method, pigments are painted to a smooth, glossy test panel, which is divided into clearly predefined black and white areas. This allows for a visual assessment of pigment coverage. To obtain an accurate percentage, a reflectometer and thickness gauge are required to measure the hiding power of the sample.

The Result of Painting the Pigment To The Test Board

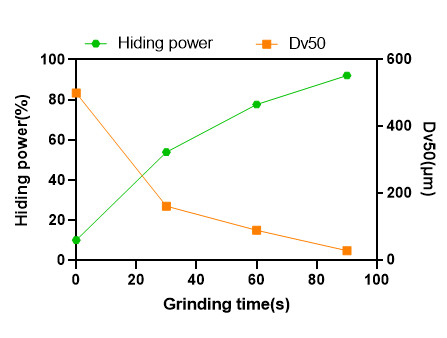

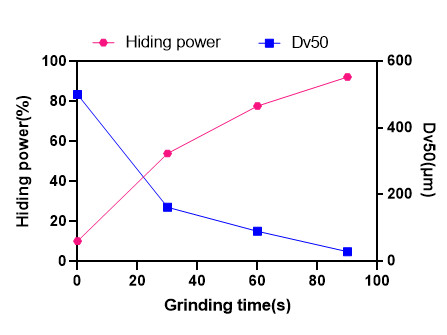

Particle Size (Dv50) v.s. Hiding Power

The particle size-hiding power curves below illustrate the relationship between hiding power and Dv50 median particle size of the two kinds of pigment, coral and lazurite with different grinding time. Mineral pigments composed of coarse particles have weak hiding power, thus showing higher color saturation and lower brightness.

In contrast, fine particle pigments, due to their smaller particle size, fill the paint surface more effectively, resulting in a more even color with greater hiding power.

The particle size of coral powder in 4 different size (include raw material, 0 second grinding) with the hiding power test results

The particle size of lazurite raw powder in 4 different size (include raw material, 0 second grinding) with the hiding power test results

Particle Size Analyzer Is More Accurate in Industrial Process

From the trend of actual coverage and particle size, the following conclusions can be drawn:

Once the pigment particles reach a certain level of fineness, that is, a sufficiently small particle size, the hiding power approaches 100%, indicating that further grinding cannot significantly change the coverage exhibited by the pigment. With the Bettersizer 2600 Particle Size Analyzer, the critical value of 100% particle size for hiding power can be actually quantified. Obviously, by using Bettersizer 2600, it reduced unnecessary grinding time in industrial processes, thereby reducing the total costs. To those pigment vendors, printing house, particle analyzer is a great tool to improve the efficiency and quality.

For more product information about Bettersizer 2600 Particle Size Analyzer, please contact ACTTR Technology right away!