Improving Electrode Slurry Quality by Using BeNano Zeta & Particle Analyzer

The manufacturing process lithium battery electrodes involves the mixtures of electrode active materials, binders, additives, and solvents. These materials are mixed together and finally forming into a slurry style, which is used to be coated on the electrode metal substrate. After the final drying process and removing the solvent, the metal substrate will be pressed and molded into the final battery electrode form.

The process of preparing electrode slurry is complicated. The slurry must be within a certain viscosity range and maintain stability for a long time. If the substances in the slurry settle or lose their viscosity during the production, it will cause problems in the later coating and drying/baking processes. A bad quality slurry may even cause the entire batch of electrodes failed. Therefore, in the front-end process stage, the quality of the slurry needs to be strictly controlled. The highly automated and high-performance "BeNano Particle Size & Zeta Potential Analyzer" is the best tool for process quality control.

NMP (n-methylpyrrolidone) is a common dispersant in the lithium battery electrode slurry manufacturing process. In the front-end process, NMP is mainly used as a solvent for PVDF (polyvinylidene fluoride), which help the materials to be evenly dispersed in the slurry and remain its stability within a certain viscosity range. Later, in the slurry coating stage, NMP can be used as a carrier to assist the slurry to be evenly coated on the substrate. And in the final drying stage, NMP assumes the pore-forming function. After the NMP evaporates, a uniform micropores structure will be produced in the coating.

"BeNano Nanoparticle Size & Zeta Potential Analyzer" is a well-known product designed and manufactured by Bettersize Instrument Ltd. It can be used to analyze the nanoparticle size and Zeta potential of materials. This instrument uses Electrophoretic Light Scattering (ELS) technology. Before measurement, an electric field is applied to the sample to allow the charged particles to undergo electrophoretic movement. Then, a laser light is irradiated on the sample solution to detect laser scattering. The frequency signal of light can be and obtained, and we can get the movement speed of the particles. Via Henry's Equation, the mobility of electrophoresis can be derived, and the zeta potential can be obtained.

In the slurry manufacturing process, by using BeNano analyzer, we can know the stability of the slurry by measuring its zeta potential. Once the zeta potential is too low, the substances in the slurry will easily agglomerate and settle, which is not conducive to subsequent coating processes, and causes quality issues.

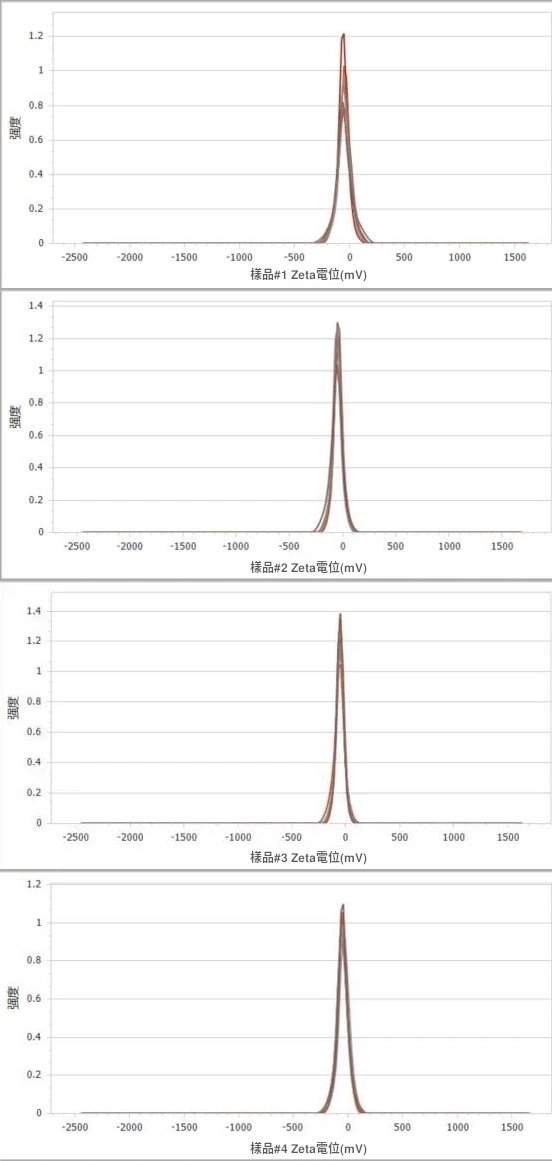

The following is the actual measurement practice of the zeta potential of the electrode slurry with BeNano analyzer. In the practice, we prepared four different electrode slurries, respectively dissolved and dispersed in NMP solvent. Because the dielectric constant of organic phase of NMP is low, in this test, we use an removeable electrode with BeNano for measurement. Each sample was tested 6 times to obtain the average value and standard deviation to understand the performance of the instrument.

Data of test results:

| Sample | Zeta Potential (mV) | STDEV (mV) |

| 1# | -53.43 | 3.48 |

| 2# | -51.84 | 1.97 |

| 3# | -50.32 | 2.46 |

| 4# | -48.53 | 3.44 |

From the test result, we can clearly see the measurement performance of the BeNano tester. The consistency of the six repeated tests of each sample is pretty good, and the reproducibility of the values are good. From the numerical results, we can know that the zeta potential of all samples are negative, which indicates that the electrode material dispersed in NMP carries negative charges. The zeta potential of the four samples are all around 50mV. A higher Zeta potential indicates a higher stability of the sample. Among them, the zeta potential of sample #4 is lower. So a further analysis is needed for sample #4 in order to know the defective points in the manufacturing process.

If you want to learn more about t "BeNano Nanoparticle Size & Zeta Potential Analyzer", please Contact ACTTR, and we’re pleased to serve you!