What Is Crosslink Density? How to Measure It?

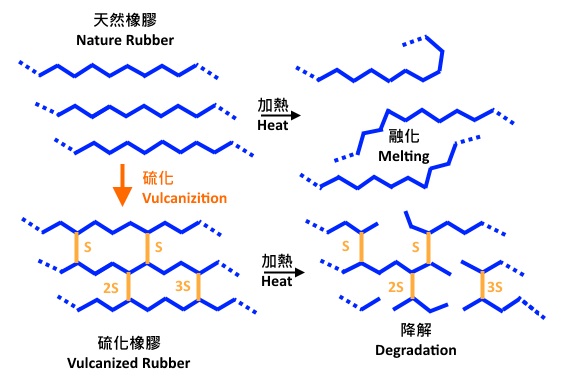

Rubber, because of its elastic & waterproof features, is widely used in our daily life and industrial products. Rubber is everywhere, such as soles, laundry gloves, condoms, gasket for pipes, anti-slip feet of furniture, rubber bands, vehicle tires, they are all rubber made. Natural rubber, it is sticky at high temperatures, but it's hard and brittle at low temperatures, in which made this material useless. In order to assign the elasticity, strength and resistance of tearing and corrosion onto rubber, it has to be heated together with sulfur. This chemical process is so called "Vulcanization". In the process, the sulfur atoms links the long molecules of rubber and generates the horizontal bonds between two rubber molecules. So, after rubber is compressed or stretched, after it is relaxed, it restores to its original shape.

The chemical interaction between sulfur and rubber is called "Crosslink". The degree of crosslinking is affected by temperature, pressure, and the time of heating time. These conditions will determine the flexibility behaviors of the final rubber. ""Crosslink Density" is used to measure the degree of crosslinking between rubber and sulfur. In industrial menufacturing, control the crosslink density of rubber, determine the quality of the final rubber products. Either too soft, or too hard in the rubber, the product will not meet the requiremets in different application. Let's think, a car with tires like rocks can slip all the time.

Hardness and Flexibility Improved After Vulcanization

Traditionally, the crosslink density of rubber can be measured by some methods, such as, "Gel Fraction", "Swelling Solvent", or "Compression Modulus". However, these methods are usually not ideally to be used in industrial production, because they take too long time before the density can be determined. Nuclear Magnetic Resonance (NMR) method, can measure the crosslink density of vulcanization of rubbers. In the recent years, NMR has became an emerging measurement method for crosslink density of rubbers and opened a new door and bright future for rubber industries.

For more information of the latest technology of measuring crosslinking density, please visit ACTTR Technology "Crosslink Density Analyzer" Product Page.