Particle Size Analysis of Cathode Materials

With the rapid development of the industries in new energy, electric vehicles, smart wearable devices areas, the research and development and production of lithium battery cathode materials are booming. Those lithium-ion battery cathode materials which have high capacity, durability, higher safety performance, and lower price, are the focus of attention today.

The common battery cathode materials are generally lithium cobalt oxide (LCO), ternary materials (NCM), lithium manganese oxide (LMO) and lithium iron phosphate (LFP), as well as the modern solid-state batteries . The particle size distribution of these materials is a key factor affecting the charge and discharge performance. An ideal particle size distribution optimizes the energy capacity and power supply of a lithium battery. Therefore, it is very important to measure the particle size distribution of the cathode material no matter in the R&D stage or mass production.

The following will show you how to measure five lithium iron phosphate samples with different particle size distributions by "Bettersizer 2600 Dry Wet Dual Mode Advanced Laser Particle Analyzer".

Bettersizer 2600 Particle Size Analyzer

Pratical Testing of Iron Phosphate

Table 1. Typical particle size values of lithium iron phosphate

|

Sample |

D10(μm) |

D50(μm) |

D90(μm) |

|

A |

0.388 |

1.057 |

3.126 |

|

B |

0.370 |

0.991 |

2.790 |

|

C |

0.387 |

0.956 |

2.970 |

|

D |

0.973 |

4.228 |

11.150 |

|

E |

0.985 |

10.19 |

18.330 |

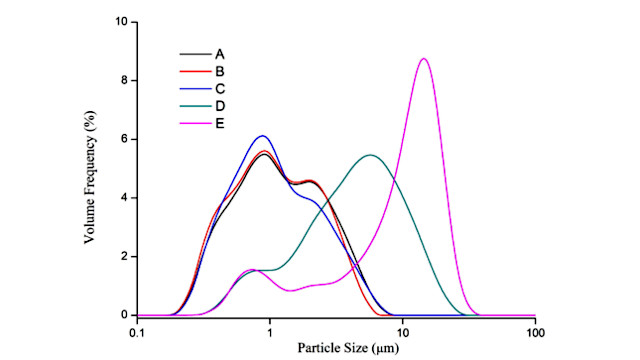

As shown in Figure 1, the average particle sizes of lithium iron phosphate A, B and C were much smaller than the average particle sizes of D and E. Generally, the average particle size of lithium iron phosphate has a great influence on the electrochemical characteristics of lithium-ion batteries. Small particles can increase the specific surface area of the active materials in the lithium-ion batteries and shorten the diffusion path of lithium ions in the battery, thus promoting the electrochemical reactivity of lithium-ion batteries.

However, if the particle size of lithium iron phosphate is too small, the particles are easy to agglomerate. This leads to a decrease of the electron conductivity and solid phase diffusion coefficient, which in turn increases the internal resistance of the lithium-ion batteries. Part of the electric current will be converted into heat energy under the influence of high internal resistance. This causes a significant amount of heat loss from lithium-ion battery, which ultimately affects the capacity and discharge performance of the battery.

A Reliable Particle Size Analyzer

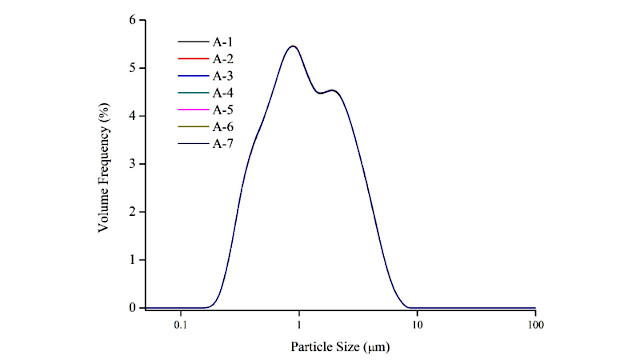

It can be seen from Figure 2 that the multiple measurements of lithium iron phosphate by the Bettersizer 2600 show a good result repeatability. The values of repeatability for D10, D50 and D90 are 0.13%, 0.07% and 0.09%, respectively, which were far below the requirements of ISO 13320 [2] . Therefore, using the Bettersizer 2600 to measure the particle size distribution of lithium iron phosphate has high repeatability.

Conclusion

The particle size distributions of the lithium-ion battery cathode materials are critical in affecting the performance of a battery. For a given anode material and cell size, the particle size distribution of the cathode material can be adjusted to optimize the energy and power of lithium batteries. In order to achieve high energy storage, stability and safety performance, it is necessary to strictly control the particle size distributions of lithium battery cathode materials. Therefore, it is important for battery manufacturers to be able to measure the particle size distribution of electrode materials quickly and easily, with the Bettersizer 2600 laser particle size analyzer.

For more information of Particle SIze Analyze, please Contact ACTTR! You're more than welcome!