How Particle Size Analyzer Helps New Toothpaste Design?

Toothpaste typically contains anti-cavity ingredients such as fluoride, and is usually has abrasives for removing stains on the tooth surface and destroy the biofilm of plaque, in order to eliminate it. The abrasives also has the effect of polishing the tooth surface. The most commonly abrasives inserted in toothpaste are aluminum oxide and silica particles. The size of the abrasive particles are usually in the range from 5μm to 40μm. With the introduction of new functional toothpastes, toothpaste manufacturers have begun to develop modern products in the trend of refinement, thus the production process has also paid more attention to the more accurate particle size control.

For example, sensitive teeth are common in patients with damaged enamel. Since the hole passes through the dentin and reaches the pulp nerve from enamel, once it is stimulated by an external stimulus, such as ice water, the nerve will be stimulated, and it causing brief and sharp pain. Anti-sensitivity toothpaste was designed by some toothpaste manufacturers, which were made of fused silica composition comprising desensitizing agents. At the same time, the particle size is controlled to a tiny level of <10 μm, so that the particles can pass through the pores and reach the nerves. At the same time, the pores can be blocked & closed by these particles.

Bettersize, a worldwide well-known instrument manufacturer, who is focusing on fully automatic particle size analyzers development. The features of Bettersize particle size analyzers are simple, durable and easy-to-use. Customers of Bettersize’s are all over the world. Bettersizer 2600 Laser Particle Size Analyer is a multi-functional analyzer with both wet and dry measurement capability inside. No matter the raw materials or finished products, Bettersizer 2600 is the best fitting instrument for R&D or manufacturing in a toothpaste manufacturer. Bettersizer 2600 allows user to quickly switch between dry and wet measurement methods and the particle size components can be quickly measured for both design and quality control purposes.

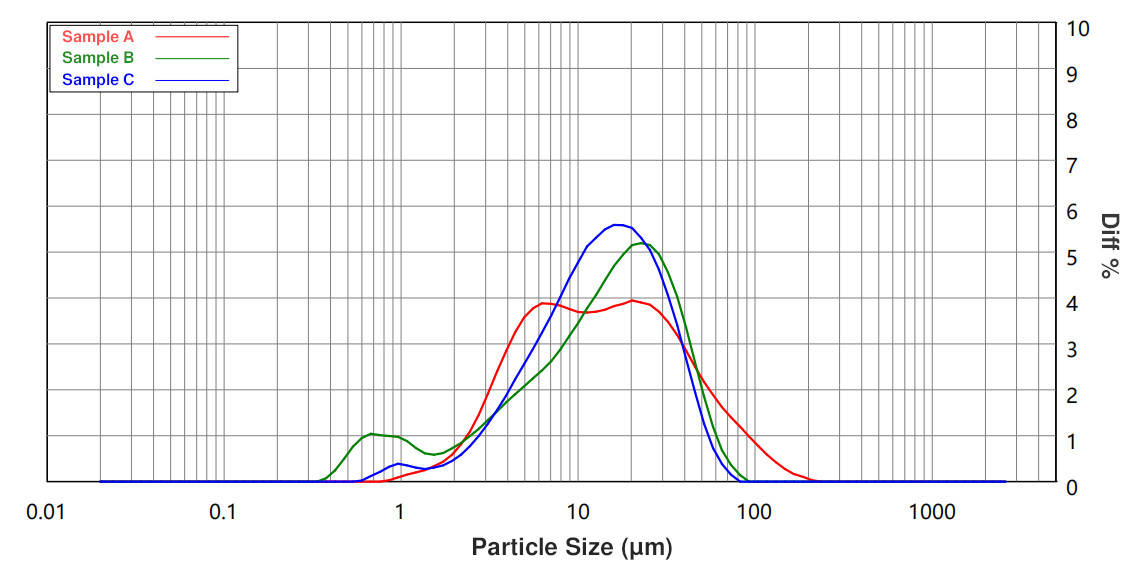

The following are the particle size distribution results obtained by measuring three brands of toothpaste samples from the market by using Bettersizer 2600:

| Toothpaste Sample |

D10 |

D50 |

D90 |

D97 |

| Sample A |

3.738 | 13.58 | 52.71 | 90.41 |

| Sample B | 1.847 | 14.60 | 38.59 | 51.84 |

| Sample C | 4.122 | 13.91 | 34.70 | 46.84 |

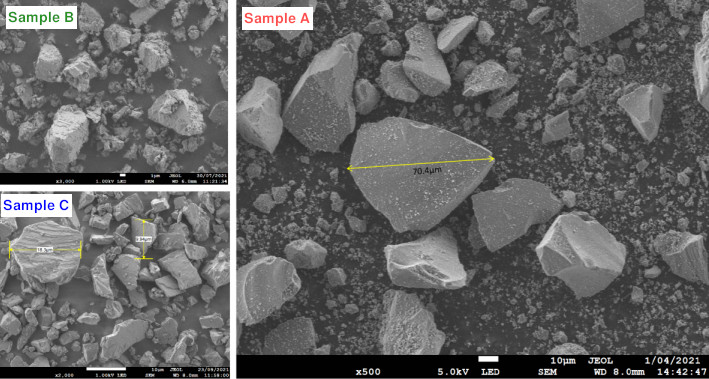

Then, we used an electron microscope to look at the abrasive particles of the three toothpaste samples. From the images, we could confirm that the measurement of the three samples from Bettersizer 2600 matches the actual particles.

Judging from the measurement results, the particle distribution of sample A is the most inconsistent one, and there are even particles larger than 40 μm. Obviously, the quality of this toothpaste is of concern. Using A toothpaste will be risky in damaging the enamel. Sample B has many particles smaller than 5 μm, which is obviously a toothpaste containing anti-allergic ingredients. However, too many fine particles will increase the viscosity, Sample B will be easy to stick and cause discomfort. Toothpaste manufacturers must research more advanced formulas in order to compensate this disadvantage. The particle size distribution of sample C is closer to the formula of most common toothpastes in the market. It is quite satisfactory and must be popular.

The high-efficiency analysis of the Bettersizer 2600 Particle Size Analyzer can help toothpaste manufacturers to develop better products as well as controlling the quality during the production process. Bettersizer 2600 is a full-featured analytical instrument.

To learn more about the superior performance of Bettersizer 2600, you are welcome to Contact ACTTR Technology, we will have dedicated personnel to serve you and provide consultation!