Monitor The Degradation of In-Service Lubricants by FT-IR

Lubricants is mainly used for lubrication inside the machine, as well as the functions of cooling and anti-rust. For example, the lubricants in an engine is an indispensable substance for its normal operation. When the lubricant gets aged and deteriorated, it will cause metal wear on the high-speed running parts inside the engine, and even cause damage to the cylinder or piston. Leading to a car, motorcycle, or aircraft stalling, even more serious consequences.

Common Instruments for Testing In-Service Lubricants Quality

An "Inductively Coupled Plasma Atomic Emission Spectrometer (ICP-AES)" is usually used for testing the wearing & tearing status of a machine by analyzing the amount of metal elements in the lubricant (usually Al, Fe, Cu, Cr, Ni, Zn). As for the quality of the lubricant itself, a "Gas Chromatography (GC)" is traditionally used in analyzing the pollution in the lubricants (such as fuel, moisture, soot). However, a Fourier-transform Infrared Spectrometer (FT-IR)", is a simpler & faster analytical instrument for lubricants quality test. In addition to checking the pollution of lubricants, FT-IR can also further analyze the degree of degradation easily.

Lyza 7000 High Performance FTIR from Anton Paar

American Society for Testing and Materials (ASTM) published a standard testing method by using FT-IR to detect the quality of in-service lubricants (E2412 Standard Practice for Condition Monitoring of In-Service Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR ) Spectrometry). The latest version was just revised in 2023.

E2412-23 International Standard Testing Method for Lubricants

這E2412-23 standard method provides two testing methods can be followed:

Direct Trending

This method Direct Trending can be used when no fresh oil is available for reference. The increase of the oxidation peak area is monitored by comparing in-service oil samples of increasing service life. If you have fresh lubricant on hand for comparison, you can use the second method:

Spectral Subtraction

This method is used when a fresh oil sample is available for reference. The spectrum of the fresh oil sample is subtracted from the in-service oil sample spectrum and yields a difference spectrum. The oxidation peak height of the difference spectrum is analyzed.

The E2412-23 standard method can monitor the contaminants in the lubricant, such as water, soot, fuel, ethylene glycol, etc., as well as the degree of degradation (majorly oxidation) by analyzing different infrared spectral segments, include nitrification and sulfation.

Oxidation is a common degradation factor during the service life of lubricants. Oxidation will lead to several problems such as increased viscosity, acidity and additive consumption. The key to determining the quality of in-service lubricants is regularly monitoring of oxidation conditions (followed by other key factors such as viscosity, additives and soot).

Testing Lubricant Degradation by FT-IR

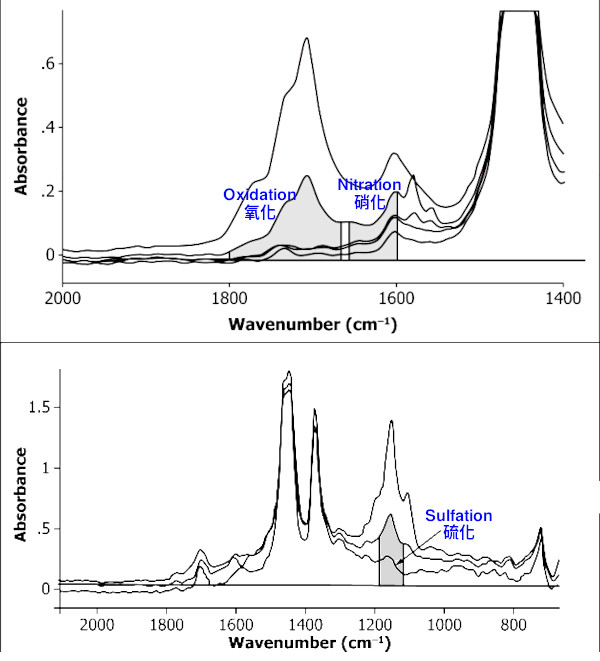

Using an FTIR infrared spectrometer, the spectrum of the sample is collected in the mid-infrared range. All organic substances will show their absorbance within this range. The FT-IR spectrum of a fresh lubricant sample is significantly different from the used one. Therefore, FT-IR is an ideal tool for tracking changes in the lubricant samples. Oxidation products have characteristic absorbance in a specific region of the spectrum (1800 cm-1 to 1670 cm-1), and the absorption intensity becomes larger as the amount of oxidation increases. Nitration products will appear in the range of 1650 cm-1 to 1600 cm-1, while sulfide products in the range of 1180 cm-1 to 1120 cm-1. The below figure is the test result from real lubricants degradation, references from E2412.

使用紅外光譜儀測量潤滑油的氧化、硝化、硫化程度

Advantages of Using an FT-IR for Testing

Shorter Measurement Time

The measurement time of the infrared spectrometer is in seconds.

Changing Samples Quickly and Easily

The infrared spectrometer uses a separate penetrating liquid sample tank to fill the lubricating oil. If equipped with a dedicated lubricating oil liquid sample tank, such as the "SPECAC Pearl Liquid Sample Cell" prescented by ACTTR Technology, the speed of sample filling and replacement can be further improved.

Pearl Liquid Transmission Cell

Easy Maintenance and Cleaning

The infrared spectrometer does not have the capillary tube inside the gas chromatograph, and there is nothing in the sample chamber space for the operator to put into the liquid sample tank.

Low Maintenance Cost

There is almost no consumable cost for a FT-IR. Sample cell is reusable. If the crystal of the sample cell are using of corrosion-resistant materials, such as ZnSe or BaF2, they can be used for years.

ACTTR Technology provides a complete range of products required for lubricants testing with infrared spectrometers. If you need further consultation, you are welcome to Contact ACTTR Technology, and we’re more than happy to serve you!