Introduction to TXRF

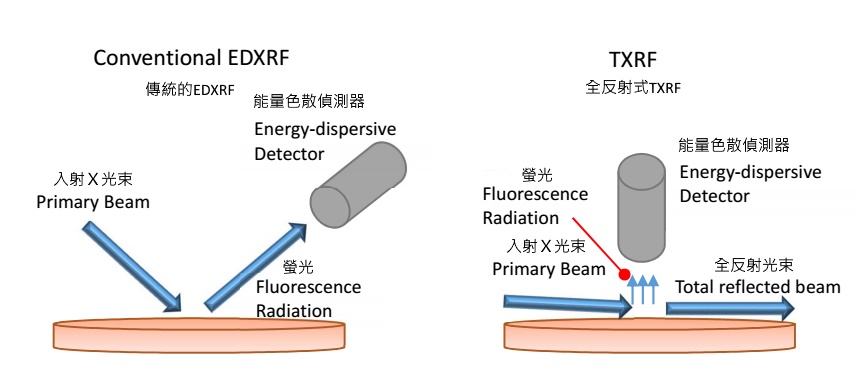

Total Reflection X-Ray Fluorescence (TXRF) is based on the technique of EDXRF. The main difference between EDXRF and TXRF is the enterance angle of X-ray beam to the sample. EDXRF X-ray beam, the sample is irradiated with a 45 ° angle, while TXRF is irradiated with a few milliradians (mrad) grazing angle.

Since the direction of X-ray beam is almost parallel to the surface of the sample, so that X-ray beam is totally reflected. It avoid absorbing in the substrate, and significantly reduce the scattering, as well as the background noise. In addition, TXRF requires only a drop of sample, which is dissolved in a solvent (5-100μL), can be measured. The substrate is dropped on the sample holde (plexiglass or quarez). After the solvent is evaporated, remains only a few nano-meters thick samples.

Difference Between TXRF And Conventional EDXRF

Due to the small amount of residual solvent or sample film, there is almost no matrix effects caused by scattering (Rayleigh scattering or Compton scattering). In practice, the great part of the scattering arising from the sample and its matrix can be eliminated. This is because matrix effect cannot be generated in the tiny residues or thin layer of a sample.

Based on the above characteristics, TXRF especially suitable for the determination of trace elements. TXRF is a fast, economic and relatively simple method for the simultaneous determination of elements. And to those atomic number higher than 11, TXRF hs pretty good detection limits in the range of 10 mg/l (ppb). Currently, TXRF has been widely used in environmental research and test, such as plants, soil, air, water quality. TXRF is a high-efficiency equipment for various types of solid, liquid, powder, alloy, and proceed non-destructive measurement.

- Summarize the advantages of TXRF, listed as below points:

- No matrix effects

- A single internal standard greatly simplifies quantitative analyses

- Calibration and quantification independent from any sample matrix

- Simultaneous multi-element ultra-trace analysis

- Several different sample types and applications

- Minimal quantity of sample required for the measurement (5 ml)

- Unique microanalytical applications for liquid and solid samples

- Excellent detection limits (ppt or pg) for all elements from sodium to plutonium

- Excellent dynamic range from ppt to percent

- Possibility to analyse the sample directly without chemical pretreatment

- No memory effects

- Non destructive analysis

- Low running cost