New Plastic Crystal Material, Colossal Barocaloric Effect

According to the global energy consumption data released by the United Nations, there are around 25% to 30% of annual electricity is used by refrigeration applications (The Importance of Energy Efficiency in the Refrigeration, Air-conditioning and Heat Pump Sectors). Most of the compressor based equipment, such as refrigerators, air conditioners, dehumidifiers, and chillers are designed based on traditional vapor compression refrigeration cycle technology. This technology uses refrigerant and its liquid-gas phase change behavior to take away the heats from the container to the external environment and achieve the purpose of cooling. And this technology is relatively mature, efficient and low cost. However, the refrigerant used in such technologies is not environment friendly. Even those new generation, so call "Environment Friendly" refrigerants, such as R32 and R410A, are greenhouse gases. The historical chlorofluorocarbons (CFCs) can even destroy the ozone layer of Earth, which is forbidden worldwide today.

In recent years, "solid-state refrigerant" materials, which are based on the physical Caloric Effects will have good chance to replace the above traditional liquid-gas refrigerant. The benefit of solid-state refrigeration technology is that there are no conventional refrigerant materials which may escape into the atmosphere and cause greenhouse effect.

At present, the related solid phase change Caloric Effects technologies generally use the materials based on the following physical effects:

- Magnetocaloric Effec (MCE)

- Electrocaloric Effect (ECE)

- Elastocaloric Effect (eCE)

- Barocaloric Effect (BCE)

Among these methods, Barocaloric Effect is base on the crystal phase change behavior of a material by pressure. When the pressure applied and released, the atoms in the material will change its spin and switch between high energy level and low energy level. And the change will cause the increasing or decreasing of entropy and it can be used in the cooling purpose. In general, those BCE materials only has very little usually small entropy change by pressure, so, this technology was rarely been paid attention by the scientists in the past. Recently, BCE related researches got great progress. Distinguish the new researches from the original small BCE, it is called colossal barocaloric effect (CBCE) today. Dr. Bing Lee and his research team in China, got a great breakthrough in CBCE technology. The neopentylglycol plastic crystal is used in the result, and the isothermal entropy change in the result is much greater than the conventional BCE materials. The research was published in Nature Magazine in March this year, 2019.

The calorimeter which was used in this research is from the well-known worldwide, SETARAM. It is MicroDSC7 Evo microcalorimeter, which is based on 3D CALVET Calorimeter measurement technology. It ensures the calorimetric measurement accuracy, sensitivity and stability in the high-pressure conditions. The following is a schematic diagram of MicroDSC7 Evo system configuration in the research.

The instrument uses semiconductor refrigeration inside, so no external cooling source, such as liquid nitrogen is needed. And the high-pressure environment is simulated by an external high-pressure gas control panel. The high pressure gas is connected via a 1/16" pipeline to the sample cell, the pressure is adjustable during the operation.

Test Result

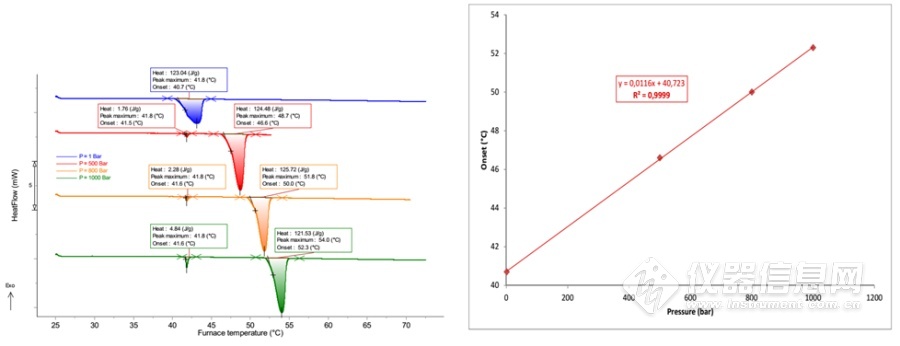

The left figure below shows the heat flow curve measured by MicroDSC7 Evo under normal high pressure conditions. The phase transition temperature of the plastic crystal material and the phase change entropy show a regular change, under different pressures. The right figure below shows the linear relationship between phase transition temperature and pressure.

Programmed Temperature : 25°C ~73°C at 0.1°C/min

Samples: neopentylglycol (NPG), pentaglycerin (PG), pentaerythritol (PE), 2-Amino-2-methyl-1,3-propanediol (AMP), tris (hydroxymethyl) aminomethane (TRIS), 2-Methyl-2-nitro Pressure control of -1-propanol (MNP), 2-Nitro-2-methyl-1,3-propanediol (NMP): up to 1000 Bar, realized by high pressure control panel.

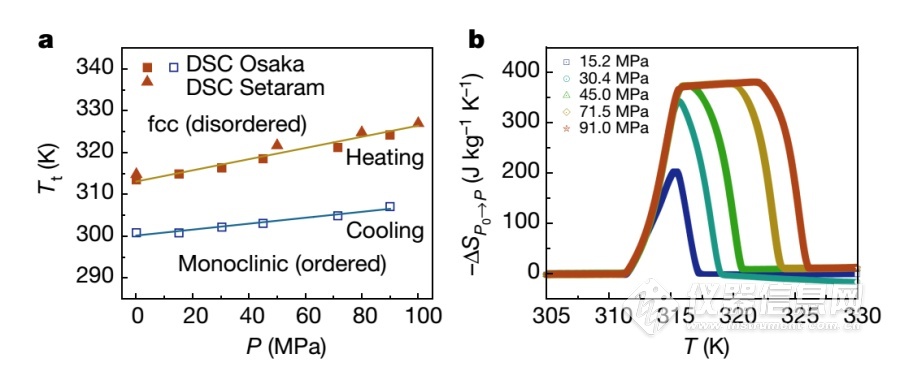

The left figure below is temperature-pressure phase diagram, which was measured by two MicroDSC7 Evo microcalorimeters located in France and Japan. The consistency of the two instrument is very good. The right figure below is the pressure-induced entropy change of the sample during heating process, under different pressures.

Please "Contact ACTTR" for more detailed calorimeter product information.