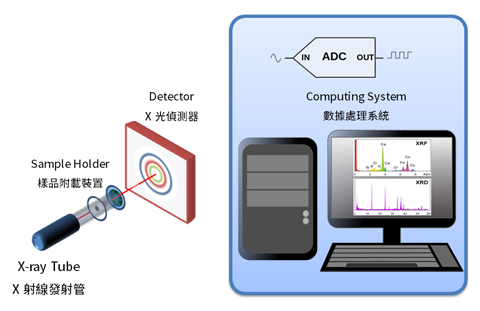

The Composition of An XRF

X-ray Fluorescence (XRF) spectrometers are non-destructive elemental analysis instruments that use high-energy X-rays to irradiate a sample, exciting the atoms within it to produce characteristic X-rays. These characteristic X-rays are then used to analyze the elemental composition and concentration within the sample. XRF spectrometers are widely used in fields such as geological exploration, metal smelting, industrial product inspection, environmental monitoring, and archaeological artifact identification.

Modern XRF spectrometers, whether benchtop or handheld, typically include the following four main components:

1. X-ray Tube

The X-ray tube is the core component of the XRF spectrometer, responsible for generating high-energy X-rays. The working principle of the X-ray tube involves accelerating electrons at high voltages to strike an anode target, such as rhodium (Rh), silver (Ag), chromium (Cr), molybdenum (Mo), or tungsten (W). This collision knocks out inner-shell electrons, creating vacancies. To fill these vacancies, outer-shell electrons transition to inner shells, releasing energy in the form of X-rays.

The performance of the X-ray tube significantly impacts the analytical precision and sensitivity of the XRF spectrometer. Common types of X-ray tubes include:

- End-window X-ray tubes: Simple structure and lower cost but weaker X-ray intensity.

- Side-window X-ray tubes: Higher X-ray intensity but more susceptible to contamination.

- Zero-window X-ray tubes: High X-ray intensity and less prone to contamination but higher cost.

2. Sample Loading Device

The sample loading device is responsible for positioning the sample for X-ray irradiation and detection. The design of the sample loading device must consider the size, shape, and state of the sample.

- Handheld XRF spectrometers: Typically use direct detection methods, with light shields around the emission source to prevent interference. Samples are usually placed directly on the probe window for analysis.

- Benchtop XRF spectrometers: Samples are placed on a sample stage for analysis. The sample stage can offer various sample fixation methods and adjust the distance between the sample, the X-ray tube, and the detector.

3. X-ray Detector

The X-ray detector is responsible for detecting the characteristic X-rays emitted by the sample and converting them into electrical signals. The performance of the X-ray detector significantly impacts the analytical precision and sensitivity of the XRF spectrometer.

Common types of X-ray detectors include:

- Gas-filled proportional counters: Work by using the interaction of X-rays with gas atoms to produce ionization, and collecting the charges in an ionization chamber.

- Solid-state detectors: Work by using the interaction of X-rays with semiconductor materials to produce charge carriers, and collecting the charges with electrodes.

Solid-state detectors are increasingly popular due to their small size, lightweight, high resolution, and high sensitivity.

4. Data Processing System

The data processing system collects, analyzes, and processes the electrical signals output by the X-ray detector, converting them into elemental concentration or content data. The data processing system typically includes:

- Multi-channel Analyzer (MCA): Measures pulse amplitude and processes the signal into an X-ray energy spectrum.

- Spectrum Analysis Software: Analyzes the X-ray energy spectrum and calculates the concentration or content of elements in the sample.

- Display and Storage Devices: Display and store the analysis data.

The performance of the data processing system significantly impacts the analytical efficiency and reliability of the XRF spectrometer.

Additional Components

In addition to the four main components mentioned above, XRF spectrometers may also include auxiliary components such as vacuum systems, cooling systems, and power supplies. These auxiliary components also influence the performance of the XRF spectrometer.