Introduction to White Light Reflectance Spectroscopy

White Light Reflectance Spectroscopy (WLRS) is a kind of method by observing broadband light(VIS or VIS/NIR) from reflection. The light reflected from the surface of the substrate with sample film, and the reflected spectrum will have at least an interference fringe in the visible spectrum. The difference from the typical Reflectometric Interference Spectroscopy (RIfS) is that WLRS uses Si Substrate as reflection media, instead of transparent substrate.

Due to the above reasons, WLRS is more suitable for today's mainstream Microelectronic Processes and related applications, which is used to measure the thickness of surface coatings or films. For example, film thickness measurement applications for microfluidic biochips, semiconductor and optoelectronic industries. Moreover, WLRS method can be applied in real-time monitoring from multi-layer and multi-samples without moving optical components. Besides, the cost and complexity of the measurement setup won’t be increased.

WLRS Spectrometer for Film Thickness

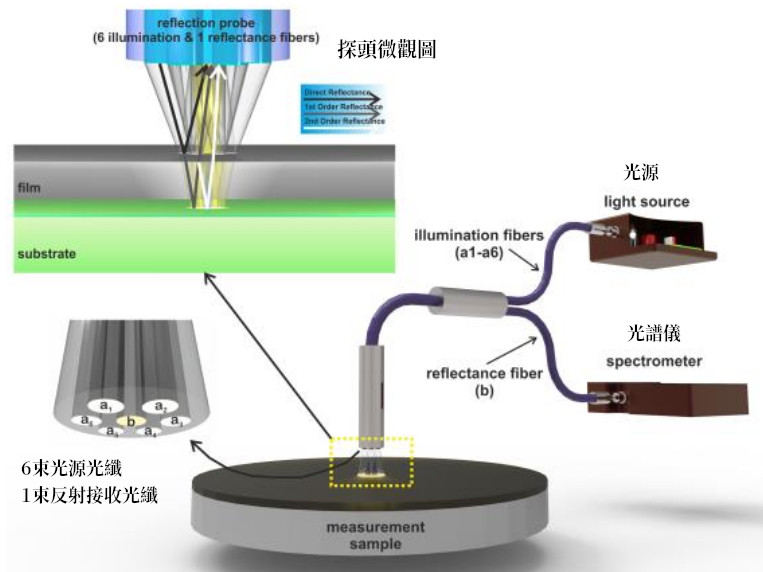

A White Light Reflectance spectrometer is mainly composed of a reflection probe, optical fibers, lamp source and spectrometer. The probe binds of several optical fibers. There are six optical fibers on the periphery of the optical fiber, which direct the illumination light from the lamp. And one additional fiber is located in the center of these 6 fibers, which transmits the reflected light to the spectrometer and later measure the film thickness or deposited layer on the silicon substrate.

After the light penetrates a single layer or multiple layers of semi-transparent films with different refractive indexes, it reaches the Si substrate with medium reflectivity. After the beams being reflected by the silicon substrate, it is collected by the central optical fiber. The spectra with interference fringes at different wavelengths are absorbed and measured by the spectrometer.

Principle of WLRS

The number and the shapes of the interference fringes measured by the spectrometer are related to the thickness and refractive index of the translucent film. According to the unique characteristics of these materials, the reflectance spectra of different thicknesses of the materials are measured. And the fitting algorithm (for example, Levinberg- Marquardt, artificial intelligence algorithm) is matched to the reflection equation by each wavelenght. After, one can simply apply the measurement results to the equation and measure the thickness of the coated or deposited layer very quickly and accurately. So, a WLRS spectrometer can be used in real-time monitoring experiments or production line. For example, monitoring the biological reaction on a biological function transducer, or real-time monitoring of semiconductor and optoelectronic material manufacturing processes.

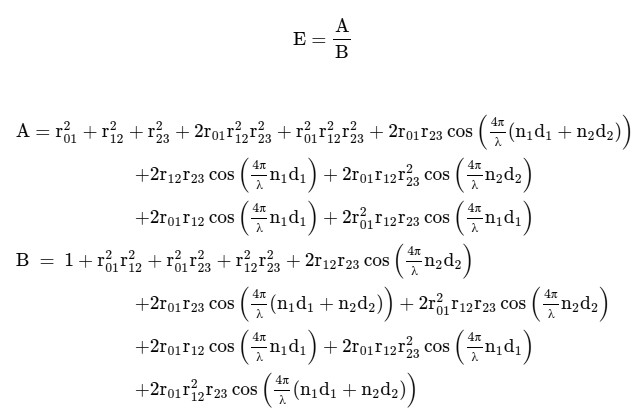

The above equation showed a dual-layer film between the air and the substrate. E is the total energy.

ni is the refractive index of the i-th layer (0 air; 1 upper film; 2 lower film; 3 silicon substrate), di is the thickness, and λ is the wavelength.

Applications

Silicon wafer thickness test

Multilayer film solar panels thickness measurement

MEMS silicon thin film measurement

Substrate refractive index measurement

Plane mapping scan

Volatile Organic Compound VOC Sensor

Volatile organic compounds will swell with some high molecular polymers, such as polyhydroxyethyl methacrylate (PHEMA) and polymethyl methacrylate (PMMA), as well as polyisobutyl methacrylate (PIBMA). By detecting the film thickness changes of these translucent polymers for the concentration of VOC.

Biological response monitoring on biosensing chip

The principle of the sensing chip is based on the principle of chemical activation, biological functionalization, and biomolecular binding reaction. The silicon dioxide coating on the silicon substrate is chemically activated by triethoxysilane (APTES). The process inserted the physical adsorption capacity for it, which adsorb γ-globulins immunoglobulin. Use WLRS to instantly monitor the thickness of the protein layer.