Improving Electrode Slurry Quality by Using BeNano Zeta & Particle Analyzer

The manufacturing process lithium battery electrodes involves the mixtures of electrode active materials, binders, additives, and solvents. These materials are mixed together and finally forming into a slurry style, which is used to be coated on the electrode metal substrate. After the final drying process and removing the solvent, the metal substrate will be pressed and molded into the final battery electrode form.

The process of preparing electrode slurry is complicated. The slurry must be within a certain viscosity range and maintain stability for a long time. If the substances in the slurry settle or lose their viscosity during the production, it will cause problems in the later coating and drying/baking processes. A bad quality slurry may even cause the entire batch of electrodes failed. Therefore, in the front-end process stage, the quality of the slurry needs to be strictly controlled. The highly automated and high-performance "BeNano Particle Size & Zeta Potential Analyzer" is the best tool for process quality control.

Read more: Improving Electrode Slurry Quality by Using BeNano Zeta & Particle Analyzer

How Particle Size Analyzer Helps New Toothpaste Design?

Toothpaste typically contains anti-cavity ingredients such as fluoride, and is usually has abrasives for removing stains on the tooth surface and destroy the biofilm of plaque, in order to eliminate it. The abrasives also has the effect of polishing the tooth surface. The most commonly abrasives inserted in toothpaste are aluminum oxide and silica particles. The size of the abrasive particles are usually in the range from 5μm to 40μm. With the introduction of new functional toothpastes, toothpaste manufacturers have begun to develop modern products in the trend of refinement, thus the production process has also paid more attention to the more accurate particle size control.

For example, sensitive teeth are common in patients with damaged enamel. Since the hole passes through the dentin and reaches the pulp nerve from enamel, once it is stimulated by an external stimulus, such as ice water, the nerve will be stimulated, and it causing brief and sharp pain. Anti-sensitivity toothpaste was designed by some toothpaste manufacturers, which were made of fused silica composition comprising desensitizing agents. At the same time, the particle size is controlled to a tiny level of <10 μm, so that the particles can pass through the pores and reach the nerves. At the same time, the pores can be blocked & closed by these particles.

Read more: How Particle Size Analyzer Helps New Toothpaste Design?

Principle of Zeta Potential and Its Importance

Principle of Zeta Potential

Zeta Potential is used to describe the potential of nano-level colloidal particles on its slipping plane, with the unit millivolts (mV) in general. Since the slipping plane of particles is the boundary separating itself and bulk fluid, by measuring the zeta potential, one can have the distance from the surface of particle to slipping plane. This distance constitutes the thickness of the electric double layer, which is the thickness of the positive and negative layers of ions on the interface between the particles and the fluid. The thickness can be used to determine the characteristics and stability of the colloid.

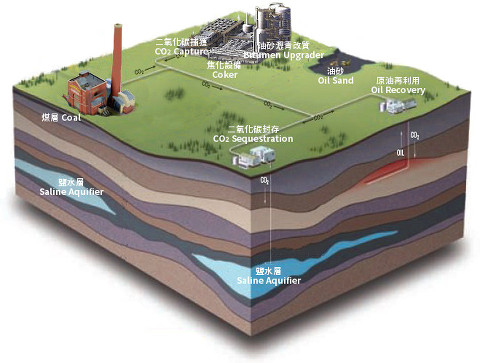

The Solutions of Fluid Adsorption in CO2 Adsorption Research

Carbon Capture and Storage (CCS) is popular research topic in the recent years. Since the mass usage of fossil fuels in power generation and industrial processes, in which caused a lot of carbon dioxide emissions to the atmosphere. It’s seriously affecting the stability of climate and results huge economic losses every year. With the development and implementation of relevant laws and regulations to limit greenhouse gas emissions, the researches on carbon capture and storage become a significant learning.

ACTTR Technology brought to you the world top class advanced adsorption analysis technology. No matter in calorimetry, Pressure-Composition-Temperature (PCT), Breakthrough Curve (BTC), Pressure Swing Adsorption (PSA), or other thermal analysis methods, ACTTR is willing to help you to complete your important researches, experiments, and new product development works.

Read more: The Solutions of Fluid Adsorption in CO2 Adsorption Research